Food and Beverage f&b Epoxy Flooring

- epoxyflooringpro.com.au

- Food and Beverage f&b Epoxy Flooring

Food & Beverage F&B Epoxy Flooring

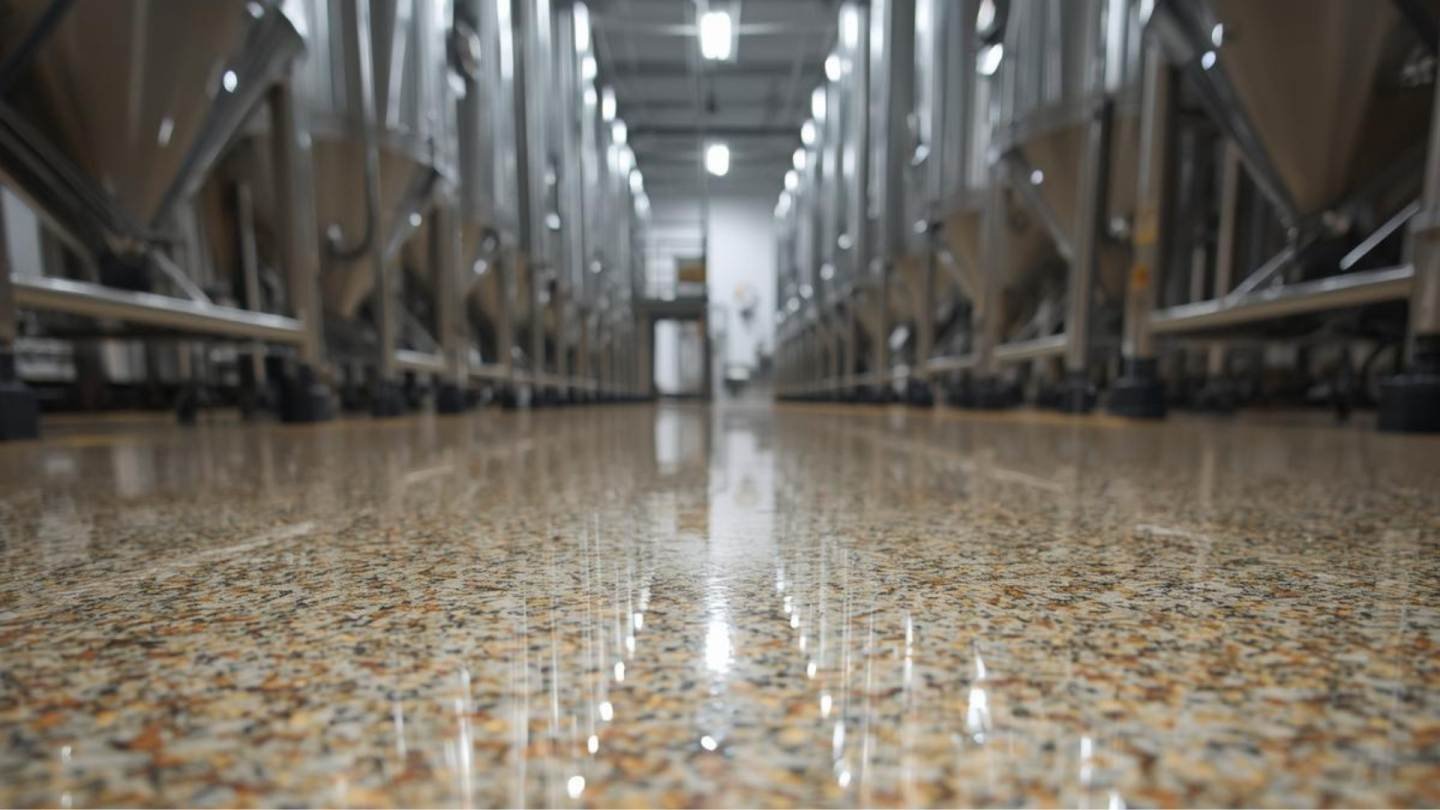

In the food and beverage industry, hygiene and durability are non-negotiable. Our Food & Beverage (F&B) epoxy flooring systems are purpose-built for food-grade and HACCP-certified environments, delivering seamless, chemical-resistant, and antimicrobial protection for commercial kitchens, breweries, and production facilities.

At Epoxy Flooring Pro, we specialise in food-grade epoxy flooring designed to meet Australia’s strict HACCP and FSANZ standards. With over 15 years of experience, our expert team installs durable and easy-to-clean epoxy and PU-cement flooring that ensures compliance, safety, and lasting performance in every corner of your F&B facility.

Why Choose Food-Grade & HACCP Certified Epoxy Flooring

Seamless & Hygienic: Eliminates grout lines and cracks where bacteria can grow.

Anti-Microbial Coating: Inhibits mould, mildew, and bacterial contamination.

Chemical & Thermal Resistance: Withstands hot washdowns, cleaning agents, and sanitising chemicals.

Slip-Resistant Finish: Ensures worker safety in wet and greasy environments.

Low-VOC & Safe: Eco-friendly and certified for food manufacturing zones.

Perfect for food processing plants, bakeries, breweries, cold storage, and commercial kitchens, our flooring systems combine compliance and aesthetics in one durable surface.

Our Food-Grade Flooring Installation Process

Surface Preparation: Mechanical grinding and deep cleaning to remove contaminants.

Priming: Apply Hychem® or Sika® food-grade epoxy primer for superior adhesion.

Base Coat Application: Install Flocrete® or APC® polyurethane-cement (PUC) flooring for high impact and chemical resistance.

Topcoat Finishing: Use Dulux® food-safe topcoat for a smooth, antimicrobial, and UV-stable surface.

Curing & Quality Assurance: Final inspection to verify HACCP and safety compliance.

Premium Food-Grade Materials We Use

We work only with certified brands trusted in the Australian F&B industry, including:

Sika®: High-performance HACCP epoxy systems for food processing facilities.

Hychem®: Solvent-free, antimicrobial epoxy coatings with chemical resistance.

Flocrete®: PU-cement flooring that withstands heat, impact, and harsh sanitation.

Dulux® & APC®: Low-VOC, food-safe coatings for kitchens and beverage plants.

All our materials are HACCP-compliant, non-toxic, and fully approved for contact environments where hygiene is critical.

Why Choose Epoxy Flooring Pro?

✅ Proven Expertise – 15+ Years of Excellence

Trusted by residential, commercial, and industrial clients across Victoria for top-tier epoxy flooring solutions.

✅ Certified Installation Team

Fully trained professionals who deliver precision workmanship and long-lasting results.

✅ Premium-Grade Materials

We use only industrial-quality epoxy and PU coatings designed for superior strength and performance.

✅ Transparent & Competitive Pricing

No hidden fees — just honest, affordable rates with exceptional value for every project.

✅ Guaranteed Customer Satisfaction

Every floor is completed to the highest standard, backed by our quality assurance promise.

✅ Get A Free Quote

Know your costs upfront before any work begins — quick, accurate, and obligation-free.

- Industrial Epoxy Flooring

- Automotive Workshop Epoxy Flooring

- Factory Manufacturing Epoxy Flooring

- Electronic Manufacturing Epoxy Flooring

- Warehouse Epoxy Flooring

- Distribution Logistics Epoxy Flooring

- Food and Beverage f&b Epoxy Flooring

- Chemical Mining Epoxy Flooring

- Healthcare Hospital Epoxy Flooring

- Pharmaceutical Epoxy Flooring

- IT Server Room Epoxy flooring

MON-SAT 8:00-9:00

0415453721

Faqs

Top 10 FAQs About Food & Beverage Epoxy Flooring

What makes epoxy flooring suitable for food and beverage facilities?

It’s seamless, non-porous, and hygienic — preventing bacteria and dirt accumulation while withstanding chemicals and temperature extremes.

Is your epoxy flooring HACCP certified?

Yes. All our systems meet HACCP, FSANZ, and Australian Standards for food safety compliance.

Can epoxy flooring handle hot water washdowns?

Absolutely. Our PU-cement systems tolerate temperatures up to 120°C during cleaning.

Does epoxy resist acids and oils?

Yes. Food-grade epoxy is chemical and oil-resistant, making it ideal for kitchens and production lines.

Is epoxy flooring safe for food contact areas?

Yes. It’s non-toxic, solvent-free, and certified safe for food handling and processing.

How long does installation take?

Most installations take 3–5 days, depending on floor size and preparation requirements.

Is epoxy flooring slippery when wet?

No. We add anti-slip aggregates to maintain traction even in wet or greasy areas.

How easy is it to clean?

Very easy — just pressure wash or mop with mild detergent. The seamless finish prevents buildup.

How long does food-grade epoxy flooring last?

Typically 10–20 years, depending on maintenance and usage intensity.

What’s the cost for HACCP epoxy flooring in Australia?

Pricing ranges from $90–$160 per m², based on coating type, area size, and compliance level.