Distribution Logistics Epoxy Flooring

- epoxyflooringpro.com.au

- Distribution Logistics Epoxy Flooring

Distribution Logistics Epoxy Flooring

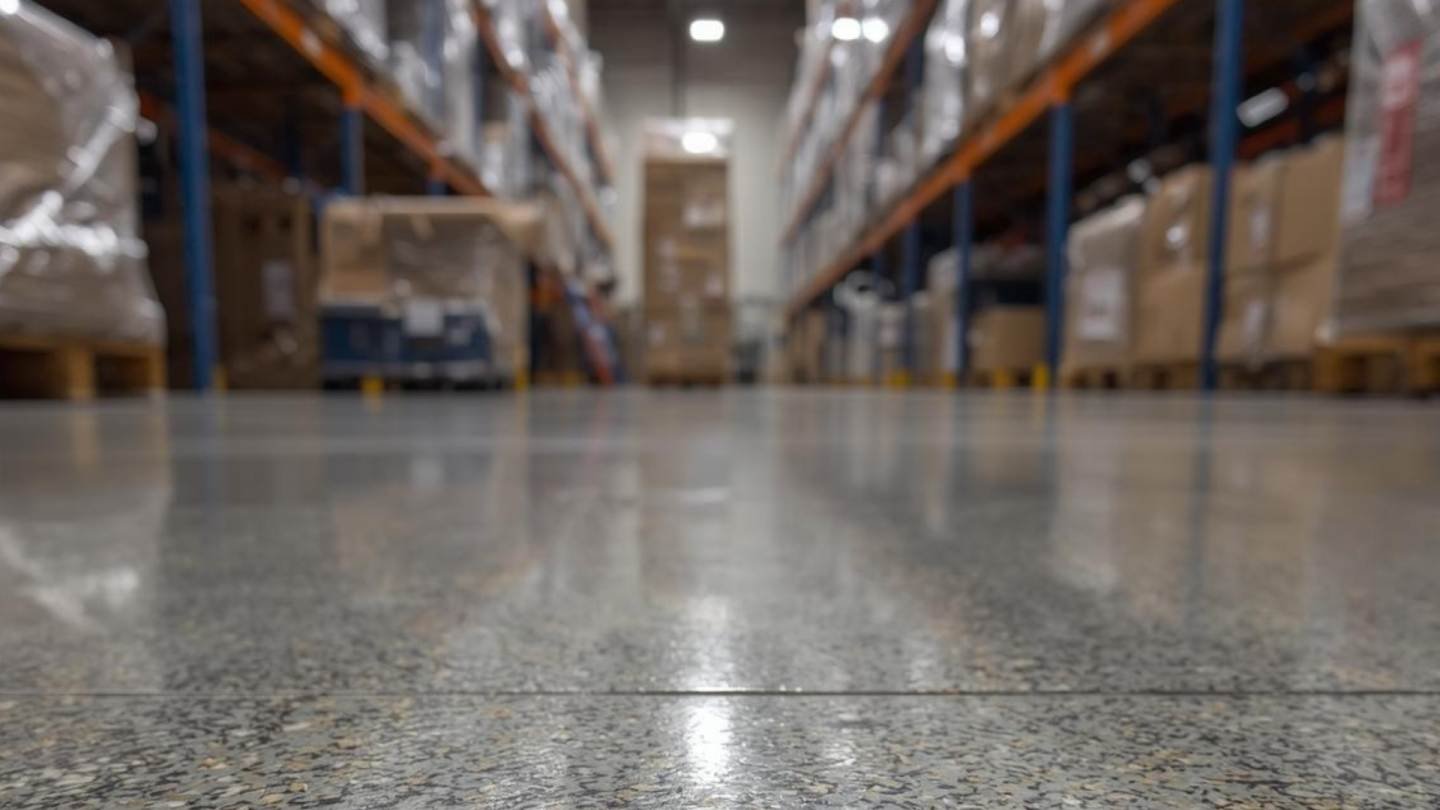

When your facility moves fast, your floor needs to keep up. Distribution and logistics epoxy flooring is engineered for high-performance, heavy-duty environments that experience nonstop traffic, loading, and operations. Whether it’s a warehouse, freight depot, or logistics hub, our epoxy flooring systems deliver unmatched durability, slip resistance, and long-term performance.

At Epoxy Flooring Pro, we’ve spent over 15 years perfecting industrial epoxy floor systems for distribution and logistics centres across Australia. Our seamless, chemical-resistant coatings are designed to withstand forklifts, trolleys, and pallet jacks — providing a smooth, safe, and efficient workspace that reduces downtime and maintenance costs.

Why Choose Epoxy Flooring for Logistics & Distribution Centres

Built for High Traffic: Designed to handle forklifts, trucks, and heavy equipment around the clock.

Slip-Resistant & Safe: Anti-slip finishes enhance worker safety, even in wet or oily areas.

Chemical & Abrasion Resistant: Withstands exposure to cleaning agents, fuel, and oils.

Seamless & Hygienic: Easy to clean and resistant to dirt, bacteria, and dust accumulation.

Efficient Line Marking: Custom colours and traffic zones improve warehouse organisation and safety.

Our Distribution Logistics epoxy flooring improves efficiency, safety, and cleanliness, making it ideal for warehouses, cold storage, and transport facilities that demand reliability under pressure.

Our Proven Installation Process

Site Preparation: Concrete grinding, oil removal, and crack repair to ensure maximum adhesion.

Priming: Application of Sika® or Hychem® industrial primer to seal the surface.

Epoxy Coating: Multi-layer application of Flocrete® or APC® heavy-duty epoxy for impact resistance.

Anti-Slip & Marking: Incorporation of quartz aggregate and Dulux® floor coatings for traction and visual guidance.

Final Curing & Inspection: UV-stable topcoat applied and tested for quality, safety, and finish.

High-Performance Materials We Use

We only use trusted epoxy brands known for industrial reliability:

Sika®: High-load epoxy systems built for logistics and material handling.

Hychem®: Solvent-free, HACCP-certified coatings ideal for hygiene and chemical resistance.

Dulux® & APC®: Durable topcoats providing gloss retention and UV protection.

Flocrete®: Long-lasting, slip-resistant epoxy flooring for safety-critical environments.

All products are low-VOC, compliant with Australian Standards, and engineered for industrial-grade performance in high-demand operations.

Why Choose Epoxy Flooring Pro?

✅ Proven Expertise – 15+ Years of Excellence

Trusted by residential, commercial, and industrial clients across Victoria for top-tier epoxy flooring solutions.

✅ Certified Installation Team

Fully trained professionals who deliver precision workmanship and long-lasting results.

✅ Premium-Grade Materials

We use only industrial-quality epoxy and PU coatings designed for superior strength and performance.

✅ Transparent & Competitive Pricing

No hidden fees — just honest, affordable rates with exceptional value for every project.

✅ Guaranteed Customer Satisfaction

Every floor is completed to the highest standard, backed by our quality assurance promise.

✅ Get A Free Quote

Know your costs upfront before any work begins — quick, accurate, and obligation-free.

- Industrial Epoxy Flooring

- Automotive Workshop Epoxy Flooring

- Factory Manufacturing Epoxy Flooring

- Electronic Manufacturing Epoxy Flooring

- Warehouse Epoxy Flooring

- Distribution Logistics Epoxy Flooring

- Food and Beverage f&b Epoxy Flooring

- Chemical Mining Epoxy Flooring

- Healthcare Hospital Epoxy Flooring

- Pharmaceutical Epoxy Flooring

- IT Server Room Epoxy flooring

MON-SAT 8:00-9:00

0415453721

Faqs

Top 10 FAQs About Distribution Logistics Epoxy Flooring

Why is epoxy flooring ideal for logistics and distribution centres?

It provides a tough, seamless surface that withstands heavy loads, forklifts, and 24/7 operations.

Can epoxy flooring handle forklifts and trucks?

Yes. Our coatings are designed to resist impact, vibration, and abrasion from heavy vehicles.

How long does installation take?

Most logistics epoxy installations take 3–7 days, depending on the site size and surface condition.

Is epoxy flooring safe for high-traffic areas?

Yes. We use anti-slip additives to ensure safety in loading docks and wet zones.

Can epoxy flooring be installed over old concrete?

Absolutely. After proper surface preparation, epoxy bonds securely to existing floors.

How easy is epoxy flooring to maintain?

It’s low maintenance — a quick sweep and mop keeps it clean and dust-free.

Is epoxy resistant to chemicals and oils?

Yes. It resists fuels, lubricants, and cleaning solvents, ensuring long-term protection.

Does epoxy flooring reduce noise or vibration?

Yes. The dense, elastic surface absorbs vibration and reduces operational noise.

Can epoxy flooring improve workflow safety?

Definitely. Coloured zones and markings help define safe pathways and traffic routes.

What’s the cost of logistics epoxy flooring in Australia?

On average, between $70–$130 per m², depending on coating thickness and surface prep.