Chemical Mining Epoxy Flooring

- epoxyflooringpro.com.au

- Chemical Mining Epoxy Flooring

Chemical Mining Epoxy Flooring

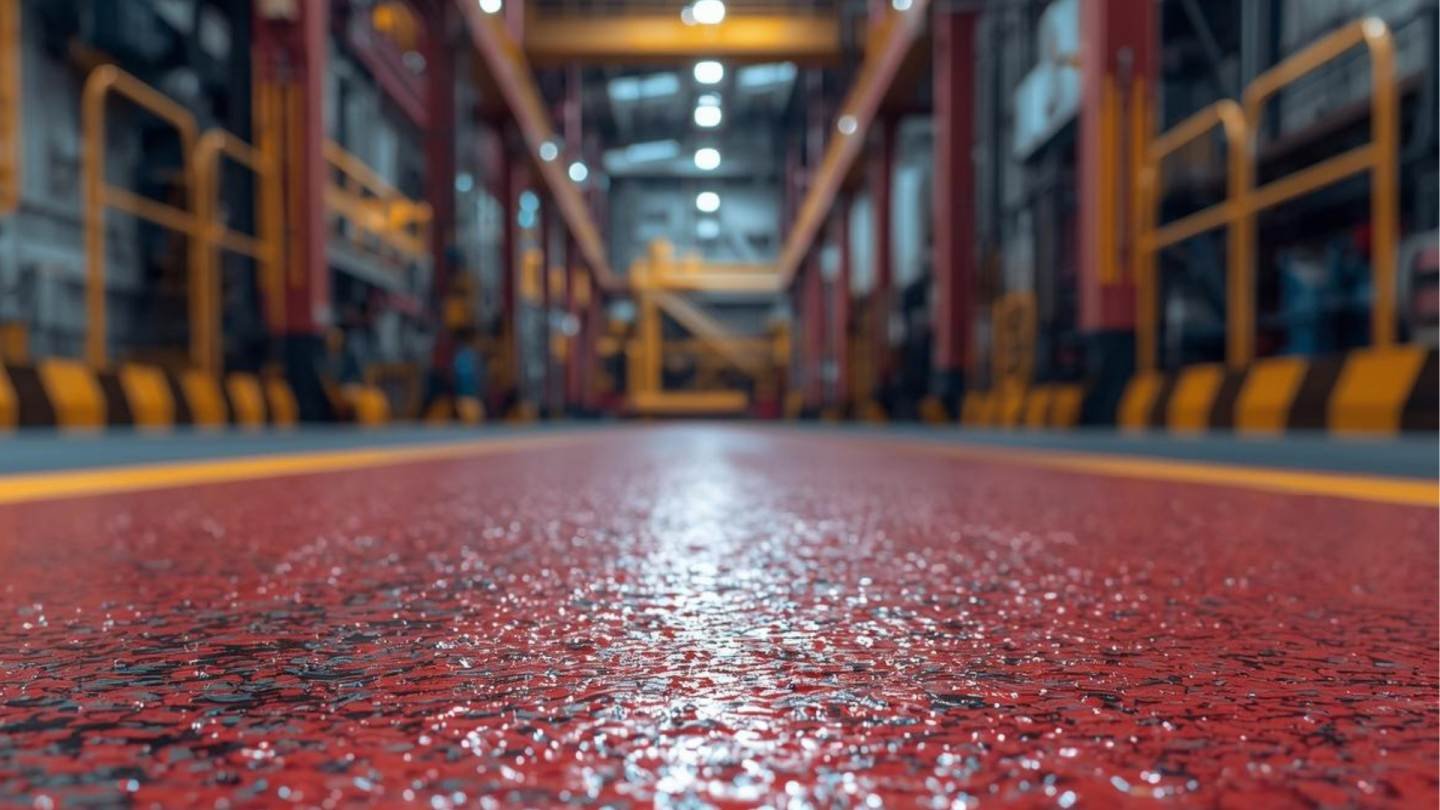

Protect your facility from corrosion, spills, and chemical exposure with Chemical & Mining Epoxy Flooring, designed for Australia’s harsh industrial environments. Our chemical-resistant epoxy systems and containment bund coatings provide unmatched protection for concrete surfaces in mining, chemical processing, and manufacturing facilities.

At Epoxy Flooring Pro, we specialise in Novolac and solvent-free epoxy coatings that resist acids, alkalis, fuels, and harsh chemicals. With more than 15 years of experience in the industrial sector, we deliver flooring systems that ensure safety, compliance, and long-term durability — even under continuous chemical exposure.

Why Choose Chemical-Resistant Epoxy Flooring

Superior Chemical Resistance: Protects against acids, alkalis, solvents, and fuels.

Ideal for Containment Bunds: Prevents leaks and contamination in bunded areas.

High-Temperature Tolerance: Withstands thermal shock from processing environments.

Non-Slip & Safe: Custom anti-slip finishes enhance workplace safety.

Seamless & Impermeable: Prevents chemical penetration and corrosion.

Our chemical and mining epoxy flooring systems are perfect for refineries, battery plants, water treatment facilities, containment bunds, and mining workshops — providing a long-lasting protective barrier for demanding operations.

Our Professional Installation Process

Surface Preparation: Diamond grinding and repair of damaged concrete to ensure maximum adhesion.

Priming: Application of a Sika® or Hychem® chemical-resistant primer for substrate sealing.

Epoxy Coating: Installation of Flocrete® or Dulux® Novolac epoxy for superior chemical resistance.

Reinforcement Layers: Add polyurethane or fibreglass mesh for high-impact areas.

Final Topcoat: Apply APC® or Hychem® UV-stable, solvent-free topcoat for long-term durability and gloss retention.

High-Performance Materials We Use

We use globally recognised industrial-grade brands:

Sika®: Novolac epoxy and bund coatings resistant to strong acids and solvents.

Hychem®: HACCP and chemical containment systems with superior chemical durability.

Flocrete®: PU-cement and hybrid epoxies for mining and chemical plant applications.

Dulux®: High-solids industrial epoxy coatings for bunded and processing zones.

APC®: Solvent-free, non-permeable epoxy resins for maximum corrosion resistance.

All coatings are Australian Standard compliant, low-VOC, and designed for long-term resistance to chemical and environmental degradation.

Why Choose Epoxy Flooring Pro?

✅ Proven Expertise – 15+ Years of Excellence

Trusted by residential, commercial, and industrial clients across Victoria for top-tier epoxy flooring solutions.

✅ Certified Installation Team

Fully trained professionals who deliver precision workmanship and long-lasting results.

✅ Premium-Grade Materials

We use only industrial-quality epoxy and PU coatings designed for superior strength and performance.

✅ Transparent & Competitive Pricing

No hidden fees — just honest, affordable rates with exceptional value for every project.

✅ Guaranteed Customer Satisfaction

Every floor is completed to the highest standard, backed by our quality assurance promise.

✅ Get A Free Quote

Know your costs upfront before any work begins — quick, accurate, and obligation-free.

- Industrial Epoxy Flooring

- Automotive Workshop Epoxy Flooring

- Factory Manufacturing Epoxy Flooring

- Electronic Manufacturing Epoxy Flooring

- Warehouse Epoxy Flooring

- Distribution Logistics Epoxy Flooring

- Food and Beverage f&b Epoxy Flooring

- Chemical Mining Epoxy Flooring

- Healthcare Hospital Epoxy Flooring

- Pharmaceutical Epoxy Flooring

- IT Server Room Epoxy flooring

MON-SAT 8:00-9:00

0415453721

Faqs

Top 10 FAQs About Chemical & Mining Epoxy Flooring

What is chemical-resistant epoxy flooring?

It’s a specialised industrial epoxy system designed to resist acids, alkalis, fuels, and other corrosive chemicals.

Why is epoxy flooring used in chemical or mining plants?

It provides a seamless, durable, and impermeable surface that prevents contamination and structural damage.

What is a containment bund coating?

It’s a protective epoxy barrier applied to bunded areas to contain potential chemical leaks or spills safely.

How long does chemical epoxy flooring last?

Typically 10–20 years, depending on chemical exposure and maintenance.

Can epoxy flooring handle acids or alkalis?

Yes. We use Novolac resin systems specifically engineered to resist strong acids and caustics.

Is epoxy flooring resistant to fuel and oil spills?

Absolutely. Epoxy provides oil-proof and fuel-resistant protection for refineries and maintenance bays.

Can it be applied to old concrete surfaces?

Yes. After grinding and preparation, epoxy adheres perfectly to existing concrete substrates.

How thick should epoxy be for containment bunds?

Generally 3–6mm thick, depending on containment area size and exposure level.

Is chemical epoxy safe for workers and the environment?

Yes. We use low-VOC, solvent-free coatings that meet OH&S and environmental standards.

What’s the cost of chemical-resistant epoxy flooring in Australia?

Typically $90–$160 per m², depending on system type, area, and chemical resistance requirements.